BADIKAN TRANSFORMER

Professional Transformer Solutions with the Experience and Expert Team of Years

BADIKAN TRANSFORMER offers you the experience of years with the expert team in a modern production facility.

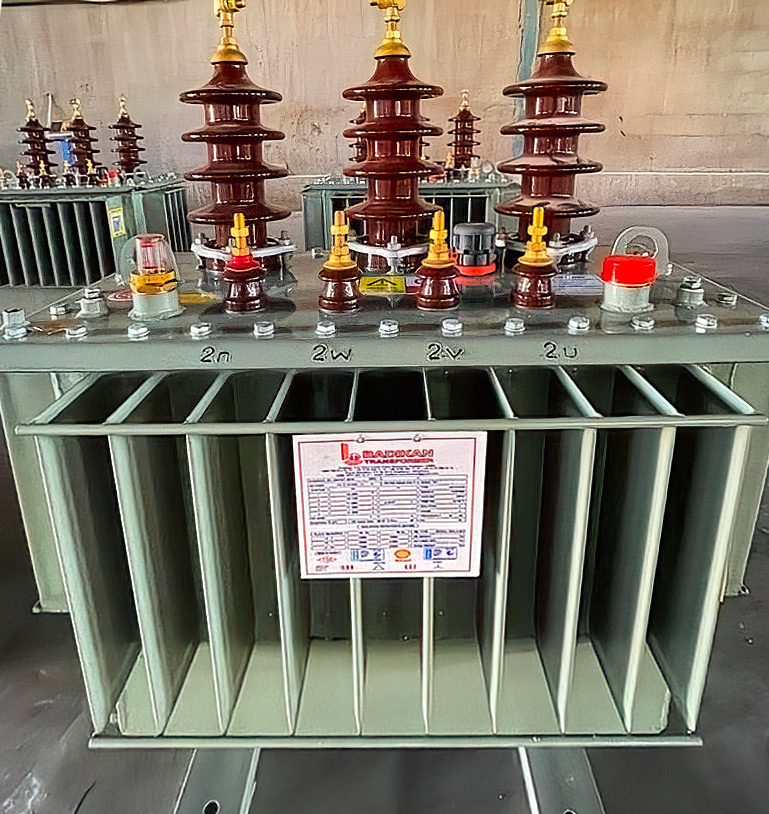

BADIKAN TRANSFORMER specializes in producing and maintaining oil-immersed special type distribution and power transformers, according to the needs of its customers.

Services

Expert Team

Professional Production

BADIKAN TRANSFORMER is always by your side with its professional team and modern production tools in production and maintenance services.

Production of distribution transformers up to 36 kV high voltage and 25-2500 kVA power

Test Center with the most advanced test equipment and expert team accepted in Turkey and worldwide

Professional production and technical services with our team who have completed World Class In-Company Trainings

Cover insulation is provided by improved rosin paper ( DPP ) thermally for low voltage winding conductor copper plate windings...

It is cored type and manufactured of M5, M4 and M3 silicon alloyed sheets with thicknesses 0.30, 0.25 and 0.23 mm of which crystals are directed.

For transformers of which core and coils are ready, coils are mounted by tightening on the core and against each other by means of bars

It is used for preservation of cooling and insulation material in oil-immersed type transformers. Transformers up to 3150 KVA are wave-walled, depending on cooling surfaces, and those with larger powers are manufactured as radiator boilers.

Production Processes

After the active part assembly of the transformers is finished, they are placed in the tank and oil is filled in a vacuum chamber, after drying at a temperature of 120 degrees in drying ovens.

The completed boilers are painted by spray method. Standard painting consists of one primer and two top coats. The total film thickness is not less than 105 microns.

All transformers produced by us are examined by Routine, Type and Special tests to ensure that they are in compliance with the necessary standards.

The Dyn 11 (DELTA/STAR neutral extracted) connection method, which has been standardized by TEDAŞ for distribution transformers up to 1600 kVA, is applied, and other connection methods can be used if desired.

Special Production Transformers

Since the day it started its operations, BADIKA TRANSFORMER has adopted product quality and customer satisfaction as its mission. One of the primary goals of BADIKAN TRANSFORMER is to constantly develop its export customer portfolio and to be among the leading transformer production companies in the world.

Please contact us for your Special Production Transformer Projects.